An Innovation Pathway of Suppository Molds: Problems, Solutions and Comparisons

An Innovation Pathway of Suppository Molds: Problems,

Solutions and Comparisons

by Süsen Gülce Erismis, BPharm MSc.

Definitions and History

The term ‘insert’ refers a semi-solid pharmaceutical dosage form

carrying active pharmaceutical ingredients (APIs) dispersed in a base that

melts at body temperature or dissolves, applied by placing into naturally

occurring body cavities aside from the mouth or rectum, such as the vagina (1).

If the insert is intended for insertion into the vagina, it is called a vaginal

insert, vaginal suppository, or pessary (2). On the other hand, if the dosage

form is prepared for administration into the rectum, it is called a suppository

(3).

Due to their numerous advantages, both vaginal inserts and suppositories

have been widely prepared in pharmacies since the 18th century to

achieve both systemic and local effects. The first suppositories were molded

into a paper cone. However paper was not the best material to mold a

suppository especially considering wettability. Therefore, metal suppository

molds made from pewter and tin were introduced in 1860. Since the first mold

was a one-piece model, it was very difficult to remove the suppositories from

the cavities. For this reason, two-piece mold models have been designed to

facilitate the removal of the suppository while maintaining its shape (4). With

the developments in material science over the years, various two-piece suppository

molds have been produced using different metal combinations and are still in

use today.

Problems, Solutions and Comparisons

The metal-based suppository molds are known for their durability due to

their composition of brass, steel or anodized aluminum. For easy removal of the

suppositories from the mold and to maintain the shape, the mold should be

lubricated with a thin layer of a lubricant such as liquid paraffin before pouring

the preparation into the mold. However, excessive use of lubricant should be

avoided, otherwise excess lubricant may accumulate at the bottom of the

suppository mold and cause homogeneity, dosage and application problems. In

addition, the metal suppository molds are too expensive, and they can cause fractures

and fissures throughout the suppositories if the mold is too cold while

opening. To overcome these problems, different suppository molds have been

designed with more affordable materials.

Suppository molds, which are most similar to metal molds in terms of

material structure, are made of hard rubber. Similar to metal molds, they can

be designed in two parts to be opened by separating from the center or in one-piece

unlike metal molds. The one-piece rubber suppository molds contain a cap at the

bottom of the mold and the suppositories can be taken out by pushing through

the top after removing the cap. Although they provide a more affordable

solution than metal molds, there is a risk of fracture of the suppositories

when opening the lid.

Flexible rubber is another material that is used make one-piece

suppository molds. After the suppository mixture has solidified, it is removed

from the mold by pushing it through the back of each cavity, thus eliminating

the risk of fracture. These types of molds are also suitable for the

suppositories that need to be stored in the fridge (5). All of those re-usable

suppository molds require a convenient packaging to protect the compounded

product.

Primary Packaging Regulations

Packaging is a crucial step of the compounding process to maintain the

stability and quality of the preparation throughout its shelf life. According

to the World Health Organization (WHO), the package must protect the

pharmaceuticals against microbial contamination, physical damage, and external

influences such as oxygen, moisture and light. They also point out that there

should be no interaction, affecting the protective function, between the

packaging material and pharmaceutical (6). Also, Good Manufacturing Practice (GMP)

of ISO 15378:2017 states that production and control of primary packaging

materials are important for the safety of a patient receiving the medicinal

product because of the direct contact between the packaging materials and the

product (7).

Traditionally, the suppositories are wrapped individually in foil

(usually aluminum) as a primary packaging material and then, they are put into a

jar as secondary package. However, foil is not an ideal form of packaging for

protecting suppositories in accordance with WHO recommendations, as it tears

easily. Therefore, there is a need for more convenient solutions for the

pharmaceutical packaging of suppositories.

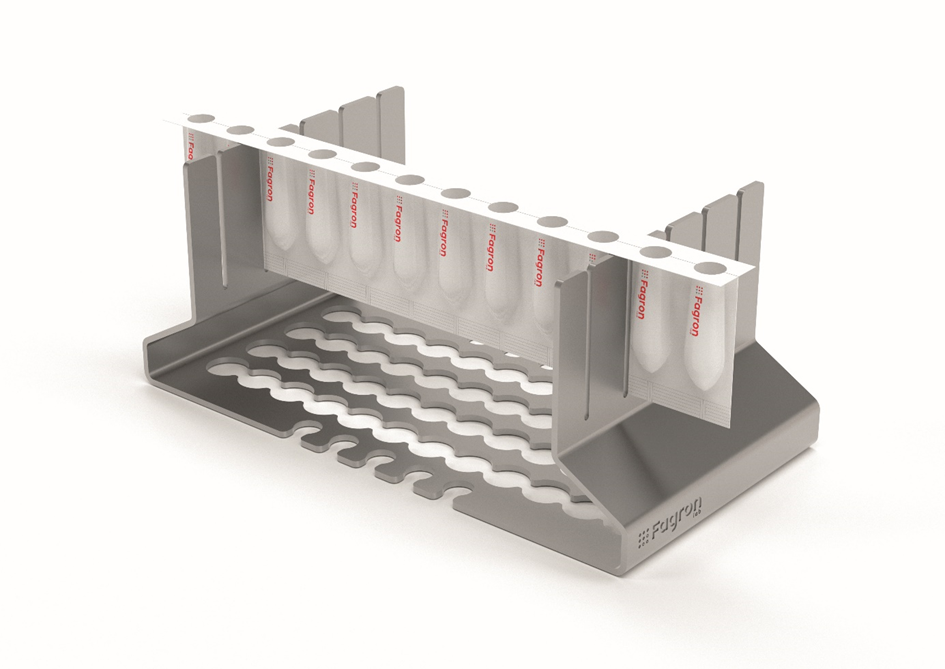

New Pursuits: FagronLab™ Suppository

Strips

FagronLab™ Suppository Strips are disposable molds that are also used as

the final packaging. The suppositories are removed from the mold by the patient

peeling the two halves of the mold apart from the bottom. There is no need for

the suppositories to be opened and re-packaged after preparation in the

pharmacy, thus they are a more hygienic and practical solution, fulfilling the

WHO recommendations, to deliver the inserts to the patients.

FagronLab™ Suppository Strips are composed from polyvinyl chloride (PVC)

material coated with polyvinylidene chloride (PVDC), reducing the permeability

of the film to oxygen, moisture and light, thus offering a stable packaging

option for the duration of the compounded beyond use date. They also have high

chemical resistance to alkalis, acids and organic solvents and are a safe

primary package as specified in the GMP guideline. This feature also eliminates

the need of using lubricants during preparation, preventing complication in

case of excessive lubricant usage.

The strips are resistant to tearing during transportation, eliminating

the risk of contamination caused by packaging material or cross-contamination

with the environment. Moreover, they are cost-efficient and valuable tools for

the compounding pharmacy, eliminating the need to purchase additional

packaging. For more information, reach out to the Fagron Academy team at facts.support@Fagronacademy.us.

Suppository strip tape allows for easy sealing of suppositories and negates

the need for heat sealing.

References

1.

NCI

Thesaurus [Internet]. ncithesaurus.nci.nih.gov. [cited 2023 Feb 22]. Available

from: https://ncithesaurus.nci.nih.gov/ncitbrowser/ConceptReport.jsp?dictionary=NCI_Thesaurus&version=23.01e&ns=ncit&code=C60933&key=644923653&b=1&n=null

2.

NCI

Thesaurus [Internet]. ncithesaurus.nci.nih.gov. [cited 2023 Feb 23]. Available

from: https://ncithesaurus.nci.nih.gov/ncitbrowser/ConceptReport.jsp?dictionary=NCI_Thesaurus&version=23.01e&ns=ncit&code=C149755&key=1151185279&b=1&n=null

3.

NCI

Thesaurus [Internet]. ncithesaurus.nci.nih.gov. [cited 2023 Feb 23]. Available

from: https://ncithesaurus.nci.nih.gov/ncitbrowser/ConceptReport.jsp?dictionary=NCI_Thesaurus&version=23.01e&ns=ncit&code=C42993&key=501421394&b=1&n=null

4.

Kravetz RE. Suppository Mold. American Journal

of Gastroenterology. 2000 Jul;95(7):1817.

5.

Preparation of Suppositories | Pharmlabs [Internet]. pharmlabs.unc.edu.

Available from: https://pharmlabs.unc.edu/labexercises/compounding/suppositories/

6.

Annex 9

Guidelines on packaging for pharmaceutical products [Internet]. Available from:

https://cdn.who.int/media/docs/default-source/medicines/norms-and-standards/guidelines/regulatory-standards/trs902-annex9.pdf?sfvrsn=82b4c57d_2

7.

Packaging

Good Manufacturing Practices (GMPs) For Medicinal Products [Internet].

www.pharmaceuticalonline.com. Available from:

https://www.pharmaceuticalonline.com/doc/packaging-good-manufacturing-practices-gmps-for-medicinal-products-0001

Comments

Post a Comment